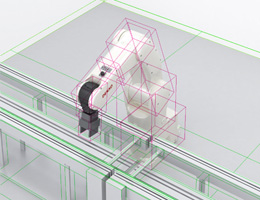

This is Denso's state-of-the-art robot controller that meets global standards. It also supports the Safety Motion function.

This function achieves harmonious coexistence of humans with robots while ensuring safety and high productivity.

Using this function, robots can be operated at a safe speed and stopped by monitoring the status of robots and humans.

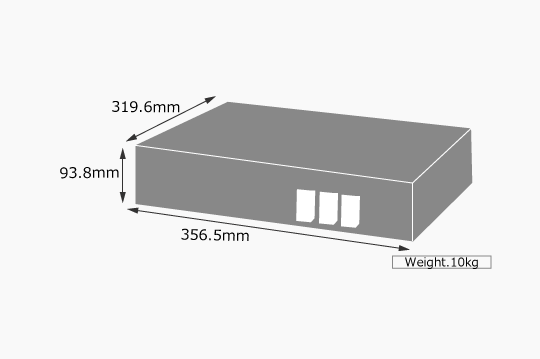

World's smallest* high-performance 8-axis controller

This small and lightweight product has a high degree of design flexibility and is space-saving.

※As of December 2016, according to Denso Wave, in the case of robot controllers for 6-axis robots (3 kw class)

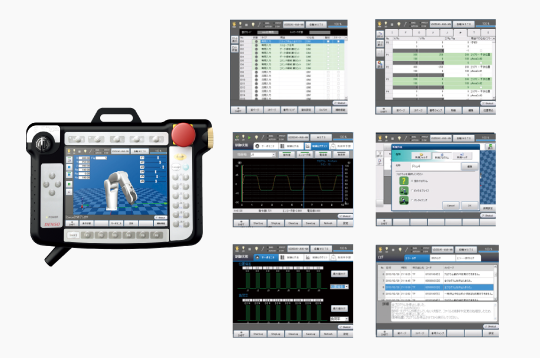

More user-friendly menu structure and enhanced

usability are achieved.

Improved GUI and functions shorten time needed

for robot introduction.

● Support for open networks [ORiN]

● Many certifications obtained

・ ISO 10218-1:2011/CE (standard, UL)

・ UL (UL)

・ PLe /SIL3 (standard, UL)

・ PLd/SIL2 (safety motion)

・ KCs (standard, safety motion)

● Support for global network standards

・ CC-Link

・ PROFIBUS

・ DeviceNet

・ Ethernet/IP

・ PROFINET

・ EtherCAT

This product enables robots to connect with and control

various devices, meeting diversified needs by

customization.

● Since control programs can be written by accessing

the provider from PacScript, robots can be controlled

from the RC8 with a provider that is compatible with

external devices.

● By developing a provider, connecting with and

controlling various products are possible.

* For details, including how to develop it, contact our

sales representative.

The control panel of the multi-functional teaching

pendant can be customized easily from WINCAPS®III.

| Item | Unit | Specifications | ||

|---|---|---|---|---|

| Power supply | Power supply capacity | kVA | 1.80 | |

| Allowable input voltage range | - | Three-phase AC200V -15% - AC240V +10%(100 V specification also available for the VP series.)) | ||

| - | Single-phase AC230V -10% - AC240V +10% | |||

| Power supply frequency | Hz | 50 / 60 | ||

| Power cable length | m | 5 | ||

| Number of axes controlled | - | Robot : 4 to 6 axes Extended-joint : 2 to 4 axes (optional) |

||

| Control method | - | PTP, CP3-dimensional linier, 3-dimensional arc(For SC series and Extended-joints, available PTP control only.) | ||

| Drive method | - | All axes all digital AC servo | ||

| Language in use | - | DENSO Robotics language (PacScript) | ||

| Memory capacity | - | User area Variable area : 1.75MB(32,766points equivalent), File area : 400MB(5,000 stepsx256 files) |

||

| Teaching method | - | 1)Remote teaching 2)Numerical entry(MDI) 3)Direct teaching(HS series, HM series) | ||

| External signal(I/O, etc.) | Universal / dedicated I/O | Mini I/O | - | Input : User open 8 points + System fix 14 points(Safety I/O-less specification:System fix 13 points)(*1), Output : User open 8 points + System fix 18 points(Safety I/O-less specification:System fix 12 points) |

| Hand I/O | - | Input : User open 8 points / Output : User open 8 points | ||

| Safety motion | - | Safety input 14 points / Safety output 6 points ※For Safety Motion specification exclusive use. | ||

| Parallel I/O board(option) | - | Bus: PCI Input: User open 40 points / Output: User open 48 points | ||

| DeviceNet slave board(option) | - | Bus : PCI Express Input : 256 points / Output : 256 points | ||

| CC-Link remote device board(option) | - | Bus : PCI Express Input : 128 points / Output : 128 points Remote register Input : 256 points / Output : 256 points |

||

| PROFIBUS slave board(option) | - | Bus : PCI Express Input : 256 points / Output : 256 points | ||

| EtherNet/IP Adapter board(option) | - | Bus : PCI Express Input : 4032 points / Output : 4032 points | ||

| PROFINET IO Device board(option) | - | Bus : PCI Express Input : 8192 points / Output : 8192 points | ||

| EtherCAT slave board(option) | - | Bus : PCI Express Input : 2048 points / Output : 2048 points | ||

| External communication | - | RS-232C : 1 line, Ethernet : 1 line(GbE : Gigabit Ethernet), USB : 2 lines, VGA :1 line(option) | ||

| Expansion slot | - | ・PCI 1 slot ・PCI Express 1 slot | ||

| Self diagnosis function | - | Overrun ・ servo error ・ memory error ・ input error、 short circuit detection (user wiring part) | ||

| Environmental condition(in motion) | - | Temperature 0 to 40 degree C, humidity 90% RH or less(dew condensation not allowed) | ||

| Safety category | - | Standard type Safety I/O Category4 PL=e Safety Motion Specification Safety I/O Category4 PL=e Safety Motion I/O Category3 PL=d |

||

| Degree of protection | - | IP20 | ||

| Weight | kg | less, Standard Approx. 10kg Motion Approx. 11kg(*2) | ||

| Standard | |

|---|---|

| RC8A | Download |

If you have not registered

The services on this member site are available only for registered customers.